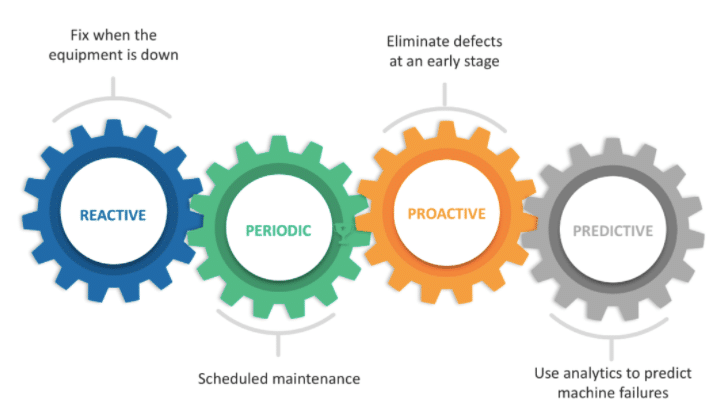

Preventative or Planned Maintenance is essential to getting the best out of your equipment. A good PM program will help you reduce costs and downtime, in turn increasing your bottom line. Investing in a scheduled preventative maintenance program today will provide major long term benefits.

Reduce Maintenance Costs – Preventative Maintenance helps to keep the equipment in optimum running order enabling you to identify and fix any issues before becoming potentially costly repairs.

Increase Safety – While it’s important you stick to your daily check routine to identify faults, it’s the role of a skilled service technician to pick up on those hard to see faults at the time of a scheduled service. Insure your staff are always safe by investing in a scheduled Preventative Maintenance program.

Optimise Utilisaition – While downtime may sound good when picking your next resort location, it won’t help you get the best out of your materials handling fleet. A couple of hour’s set aside for a scheduled service can save you multiple hours in breakdowns and optimising your fleets productivity.

Increase Profits – As stated above. By reducing downtime and overall maintenance costs while providing a safe working environment, your business can perform to the best of its abilities. A good preventative maintenance program will be reflected in your bottom line performance!

Don’t forget, your forklift is an asset. By investing in it today, you’re effectively increasing the life and value of that asset. This will be reflected when it comes time to trade up. Operators will appreciate a Preventative Maintenance program and will go out of their way to look after the equipment.

Halbro Forklifts have a team of skilled service technicians and experienced staff to implement and oversee a preventative maintenance program.

Contact us today to discuss your requirements.